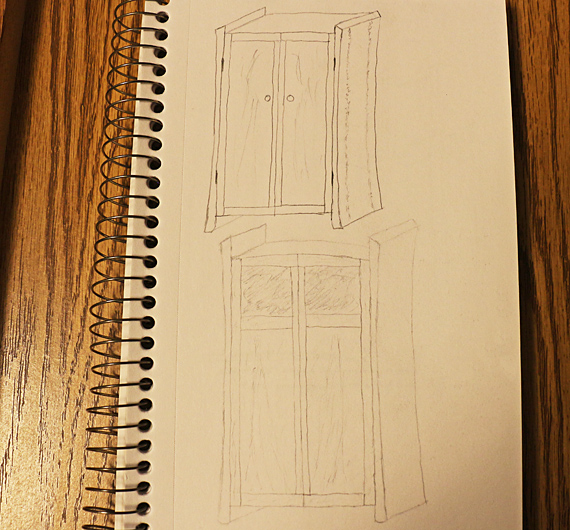

You have an idea for a piece – a compelling, strong idea. The more you think it through, the more it grows and the more you think, “I can do this. It’s going to be worth it.”

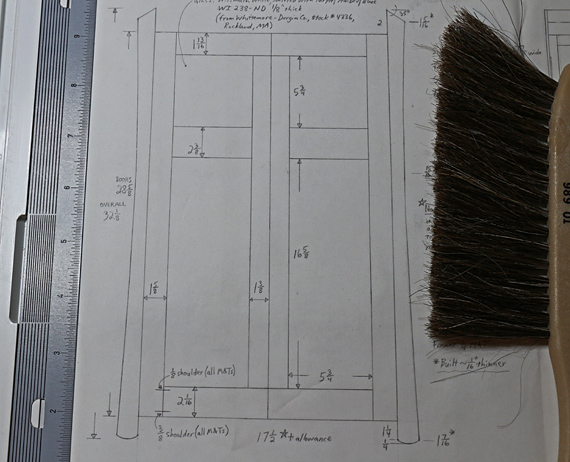

You research design options, wood, and joinery. Things seem to be coming together. Along the way, however, you find some dangerously impressive work of the general type that you have in mind. This happens to me when I look at woodwork by Tim Coleman, John Cameron, and Craig Vandall Stevens, to name a few. How did they do that?

And you begin to wonder: “OK, it’s not a competition but, good heavens, I love that piece that I’m looking at on the internet and I know, or at least I feel pretty sure, that I will not love mine as much when I finish it – if I make it at all, that is.”

Now what to do? Sometimes it is difficult to avoid outright copying strong ideas – to simply build again what has already been built just fine – but that is not what you set out to do, and not your road to fulfillment.

Or do you give up part way into the design process and say “Good enough. I know I could do better but why bother?” Will you tank the design, knowing that no one else will know? Or don’t sing at all if you’re not Pavarotti?

That’s silly. You have a voice. Use it, plain or fancy, innovative or derivative. If you work at it, if you do not lull into laziness, the piece you have in mind is going to be at least good, maybe very good, and who knows, maybe even great. Humility and confidence are willing partners.

But here is what you do not expect. If you really put mind, hand, and heart into it, I will bet that the piece is going to be better than you think.

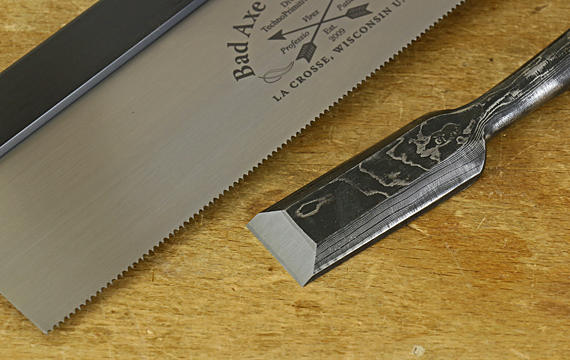

This is perhaps the biggest secret and the magic of creative work. Trust yourself! Yes, it could flop but if you are diligent and you have developed a decent level of skill, the odds are actually in your favor. You are working hard, you are necessarily taking a risk, and you do not, you cannot, know quite what the outcome will be . . .

Until it is there!

And when it is there, it will be more than the sum of your ideas and your craft. In fact, you likely will look at it sometime hence and think, “How did I do that?”