The companions seated at a restaurant table with an avid woodworker may find it odd that while they are studying the menu, the wood guy is studying the table. But much can learned by observing wooden structures in the wild, and so it was at a recent outing – just a few moments to choose the sashimi, but now let me see what’s going on with this table.

The big split (above) is easy to diagnose. There is a breadboard end cap running cross grain to the main section, and is no doubt glued along its entire length. It probably took only a year or less for the wood, probably dark red meranti, to split during a dry season when it was restrained from shrinking across the grain by the long grain length of the end cap.

Was the maker unaware of the problem inherent in the construction? Was it made just to look good at delivery without regard for its fate? One wonders.

The split appears to be along an edge joint. As I have discussed in an earlier post, this is not a coincidence. The edge joint was weaker than the wood, a situation with many possible causes and that woodworkers try hard to avoid. My extensive series on the edge joint can help prevent this from happening to your work!

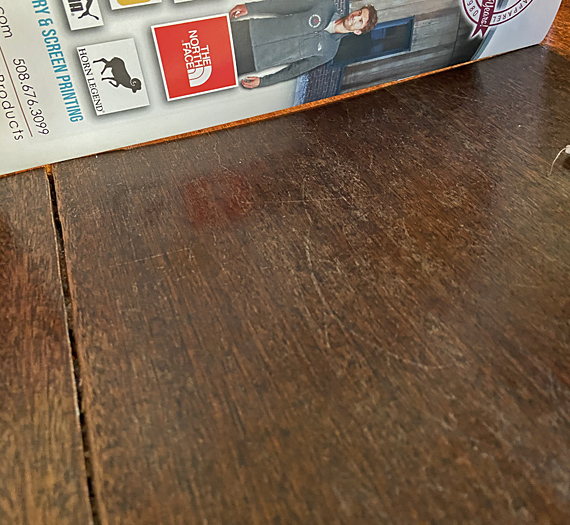

What about the concavity in the top surface? In the photo just above, I am demonstrating the warp in the surface using the straight edge of the spine of a brochure. (Sorry, I didn’t have my Starrett with me.) Seasonal movement of flatsawn wood perhaps? No, the wood does not look flatsawn, and I am almost certain this same cup is present year round, and eventually in most of the tables there.

The finish on the tabletop eventually deteriorates from repeated wetting, scratches, and perhaps ultraviolet light exposure. Liquid water, inevitably and repeatedly on a restaurant table, can then enter the wood fibers near the top of the board and swell them. The top surface of the board wants to get wider across the grain. But each time the fibers swell, they are compressed against each other, probably aggravated by the top of the board being relatively restrained from expanding by the drier bottom of the board, along with other aspects of the construction. The fibers undergo permanent deformation; they get crushed. This is compression set.

Later, when the top of the board re-equilibrates to a drier state, the crushed fibers want to shrink the width of the board. The board thus becomes concave on its top surface. This effect is irrespective of the usual come-and-go of flatsawn cupping, which may be additive to it.

It is important to realize that these hygroscopic forces of wood movement are stronger than the wood structure itself.

Taking a walk on a wood deck later that day, the boards showed another example of this.

We have to consider how the woodwork we make will fare long after it has left our hands. It is good to remember Yogi Berra’s advice, the title of this post.

[Who is the player with the most World Series championshhips in Major League Baseball history? Yup, it’s the great philospher himself, Yogi.]