In previous posts, I described my router table and fence. They use a simple approach without router lifts, drop-in fitted plates, table slots, miter gauges, or proprietary tables and fences.

Yet upon noticing a handy-looking router table fence micro adjuster in a catalog, I was tempted. It looked straightforward enough. I studied the item in the store and figured, 24 tpi on the lead screw, well, let’s see, that’s 1/24″ per turn, 1/64″ = 3/8 turn, .004″ = about 1/10 turn. No gradation markings. . . forget it. It would not be easy to move the fence a discrete tiny numerical increment, and why else would I want a micro adjuster?

So how do I accurately adjust my router table fence? The answer is: as directly as possible, preferring consistency over absolute measurements, and using one-sided tolerance woodworking techniques which are easily compensated. For example, if I want grooves for a drawer bottom to be 3/8″ from the edge, I set the fence to a reasonably close 3/8″ and plan the work to cut all the parts with that setting. As an example of one-sided tolerance, to cut a rabbet, use the part that will fit in the rabbet to adjust the fence, adding just a hair of depth. The slight excess of lip is easily trimmed after assembly, whereas too little depth would require lots of corrective planing.

There are rare circumstances, however, when it is helpful to move the fence a tiny, specific numerical distance. If I make a cut with the router table and, for some reason, I do not want to alter the mating part to fit, I use .001″ resolution calipers to measure the difference between the cut part and the mating part and thus the amount I need to move the fence to accurately finish the cut.

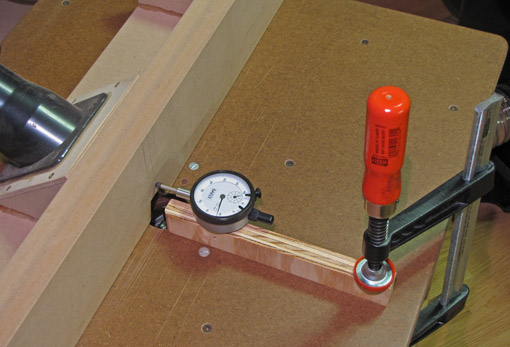

I use one screw to attach an inexpensive dial indicator to a stick which gets clamped on the table with the tip of the indicator against the fence. The fence is then moved according to the direct readout on the indicator. It would be possible permanently rig a dial indicator to the fence and table but that would be too fussy for rare use.

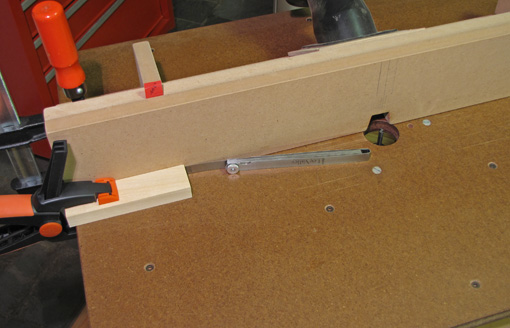

Alternatively, without a dial indicator, to retract the fence, clamp a block to the table near the end of the fence to register the initial fence position, loosen that end of the fence, interpose a feeler gauge, snug the fence up to it, and retighten the fence. To advance the fence, set the feeler gauge against the fence, snug up and clamp the block against it, loosen the fence, remove the feeler gauge, bring the fence against the block, and retighten the fence. The increment at the bit is half the measured amount at the end of the fence. These procedures are far easier and more intuitive to do than to read or write them!

For bit height, I also like to work directly, but if a measured movement is needed, the very fine adjuster with marked gradations on the Bosch 1617 router works well.

In summary, I adjust the router table fence with direct, low-tech methods the vast majority of the time, and very occasionally employ simple methods using basic multipurpose tools (that I already own) to produce specific measured adjustments.

And I saved myself from another mind-cluttering, special-purpose gadget.

Hi Rob,

I enjoy your blog, and admire your work. Also, I used your router table as a guide to build my own. Thanks!

I came across a neat micro adjuster jig that I thought you might enjoy.

http://americanwoodworker.com/blogs/tools/archive/2009/09/16/5-router-jigs.aspx

Thanks for the comment, Bryan. I hope your router table is working well for you.

The micro adjuster that you referenced looks essentially like a shop-made version of the one for sale that I was looking at. If someone really wanted that kind of microadjuster, I guess it would be better than the store bought version since at least you have a choice of screw pitch. 10-32 or 1/4-32 would probably be better choices.

Rob

I made a micro adjustable router fence from a plan in an old Fine Woodworking magazine. October 2000 No. 144! you should be able to get a back issue!

It is designed Pat Warner fence!

It is strong, flex free and repeatable down to .001!

Here is the link,

http://www.patwarner.com/router_table.html

It is an awesome fence!

Glenn Boyle

Old furniture makers made masterpieces without micrometer adjustments or routers. We can spend money on tools or spend time developing skill.

A simple tool in the hands of a someone skilled will always produce better work than a complex (and perhaps expensive) tool in the hands of someone unskilled.

I like Pat Warner’s approach to the router table. It is the inspiration for mine as I mentioned in the post on building a router table. His router expertise is tops. But I think his fence would be too much for my purposes.

I agree, John.

Rob

You have missed the main point of a fence like the Incra and that is repeatability alongside the micro adjustability.

To be able to switch back instantly to a previous setting saves oodles of time.

Chris,

Thanks for the comment and for reading.

I understand the value of repeatability as well as micro adjustability. In my opinion, both of these are usually obviated by what I call direct methods of working which utilize the principles of consistency and one-sided tolerance.

Furthermore, both repeatability and micro adjustability, when they are occasionally needed, can be achieved with low tech, non-specific tools. When I need a repeatable fence setting, I simply clamp a piece of scrap wood up against the front (or back, as appropriate) edge of each side of the fence.

I acknowledge that there are times when I would probably find something like an Incra fence on my router table to be handy. My point is that for the other 99% of the time, it is expensive over-engineering. Worse for me, is that it would interfere and work against the type of direct, intuitive methods of work that I prefer and that give me the results I want.

That said, I also acknowledge that there are different successful approaches to virtually everything in woodworking. So, while, no, I do not miss the point of a fence like the Incra, I also appreciate the validity of different approaches.

I thank you for your comment since it caused me to think through this again, and, hopefully, articulate it in a useful way.

Respectfully,

Rob

Chris,

I agree with Rob that there are a many different ways to approach woodworking – for some people ultra precise fences are a valid tool – so please don’t take offense at my comment.

Repeatability is an issue for a shops that reproduce pieces over a period of time. However, even shops that do that kind of work often make jigs and save them – repeatability with jigs is pretty much guaranteed and there isn’t any time spent switching back to previous settings – the jig is the setting.

However, for one-off projects with small runs of similar parts, fine tuning can be done by running test pieces until you nudge in the exact measurement you want. When the pieces are cut the entire guide setup can be broken down with no loss because it may never be needed again.

I’d rather save the money to buy wood.