Oops, I had a SawStop “event.” But it was not my flesh that met the blade. Rather, I foolishly forgot to reset the miter gauge fence when setting up an angled crosscut, and ran the aluminum fence into the blade, and . . . boomp! So, I had to send out the damaged blade for repair along with my spare blade that was damaged 14 years ago when I was setting up the new saw. This, plus buying a new SawStop brake, made for an expensive goof up. All told I’ve lost use of the tablesaw for four weeks.

But, I’m doing just fine, thank you. In fact, the episode has reinforced my longstanding conviction and advice that the tablesaw is not the key machine in the furniture maker’s shop. In my view, that distinction belongs to the bandsaw, especially when it teams up with a good thickness planer, or better yet, a wide jointer-planer combination machine.

Far from being a hand tool purist, I was happy ripping on the bandsaw with surprisingly little clean up required with a handplane. I also cleaned up lots of 15/16″-thick, 3″/3 1/2″-wide pieces by standing them on edge going through the DW735 planer with the Shelix cutterhead. I made sure the rollers and bed stayed clean, and it went well.

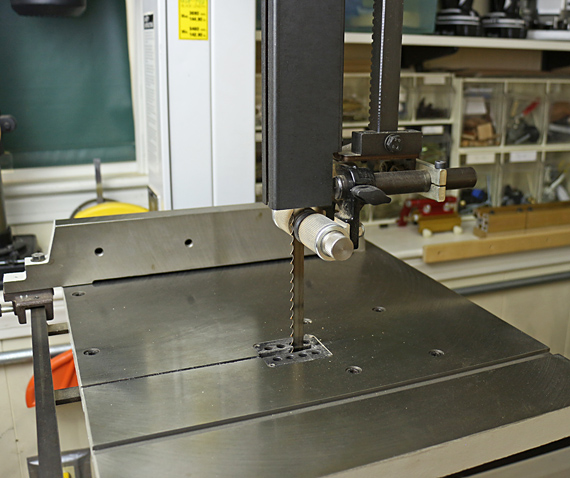

“What about crosscutting,” you say, “that’s not likely to go well on the bandsaw.” Well, using the little miter gauge that came with my bandsaw, the crosscuts are pretty accurate and not too rough even with my all-purpose 3-tpi blade.

Which brings me to another longstanding conviction and advice. And that is the importance of shooting. It was a pleasure to clean up the bandsawn crosscuts cleaner and more accurately than even the tablesaw could do. Shooting is so critical to accurate furniture making that I suggest sparing no effort and tools to set up good systems for end grain and long grain shooting. (I’ll describe my current long grain setup and have some tips in an upcoming post.)

I won’t be selling my tablesaw – it does a lot of tasks efficiently and well. However, I do want to reinforce this advice regarding machines, especially for woodworkers setting up or upgrading their shops:

- The first machine to buy is a good portable thickness planer. The DW735 has no peer.

- As soon as you can, buy the best bandsaw you can. Steel frame style, at least 12″ resaw height, preferably something close to 2.5 HP or more.

- Get a 12″ jointer if you can.

- And sometime, yes, you’ll probably want a tablesaw.

Most important, no matter what tools you have, build things.

Rob,

Ouch. Glad it was the miter gauge and not a skin test of your SawStop. BTW, I’ve never done such a fool thing, no sir never. :-)

Your advice is spot on. While I will not do it, I sure look with coveting eyes at the floor space taken up by my table saw and the 8″ jointer. For the last couple of years the table saw has been shoved into a small space next to the wall. I can still use it to crosscut short (<40") pieces but that is about it. I don't miss it and if I could recover even a 1/4 of the original cost it would be gone.

ken

Ken,

Haha, well I guess twice in 14 years is not too bad, or as the guy at the store said, “The system should be tested once every 14 years.”

Yea, and an excellent bandsaw costs a lot less than a similar grade tablesaw.

Rob

Rob,

Your original posts about bandsaws and the Hammer combo machines gave me a lot of confidence when I was building my tiny shop. I knew I would never be able to fit a table saw but I also knew the shop would be better than my bench located in the kitchen! Maybe a table saw would be more efficient or I don’t know what I am missing but I do fine without. Thanks for the great site!

Sam

I don’t understand why DeWalt doesn’t have a factory config with the DW735 planer with the Shelix cutterhead. I would buy it. The fact I have to do it myself means I end up thinking it’s too much of a hassle so I don’t buy it.

Yup, I agree, Joe. Especially since Rikon is trying to compete with a similar-appearing 13″ portable planer with a segmented cutterhead for about $700. It is not in the same class as the DW735 + Shelix. The DW is a better built machine, and the Shelix cutters are arranged in true helical rows so the cutting edges, which are themselves radiused, meet the wood at a shear angle. The Rikon has segmented cutters but the rows are straight, and so the cutters, which have just straight edges, meet the wood square on, not in a shearing cut like the Shelix.

Joe, check out my posts on the Shelix installation (in Series Topics). You can do it, it’s not that hard, and it’s really worth it – probably a once in a lifetime job for most small shop amateur woodworkers.

Rob

I had a homemade tablesaw and had saved $$ to get a sawstop instead. I had been getting into hand tools and was interested in milling my own lumber. I considered the noise and dust in my basement workshop.

So I got a good 14″ bandsaw for a bit less and even disassembled my tablesaw. I don’t miss it. I also got a cheap tracksaw that I’m not using all that much. Less space, less dust, less noise.

I’m not doing repetitive cuts or production. If I was, I’d be looking at a planer.

Sounds good, Tom. You’re probably getting a good workout with handplanes! But yea, the quiet is nice.

Rob

Great advice, thank you. Regarding shooting, do you recommend a specialized Shooting Plane or is a good bench plane adequate?

Pascal,

Shoot with what ya got!

For end grain shooting:

Best: a dedicated shooting plane. I use the Veritas shooting plane, and love it.

Good: a bevel-up bench plane. More mass is better than less mass.

Adequate: a bevel-down bench plane. I used a BD jack for shooting for years. It’s wasn’t ideal but it got the job done. Don’t let anyone tell you that you “can’t” cut end grain with a bevel-down plane. Not ideal, but you can.

For long grain shooting:

BU or BD bench plane is fine, as long as it has decent mass and stability. The side has to be square to the sole.

I like my L-N #9 “iron miter plane” because its beefy, boxy, and handles well with the “hot dog” handle.

Above all, the blade must be SHARP!

Good luck,

Rob

Hmm, this would make a good post for the future.

Thank you! Yes it would be a good post subject. For now I have been using a regular bench plane, and lately started looking at dedicated shooting planes. They are very pricey! Anyway if you ever do a post on them, I was wondering why Veritas offers both the Shooting plane and the Miter plane? From what I understand the Miter plane is for shooting as well.

Pascal.