Here is a very direct approach to mortising with a router that works especially well for mortising legs.

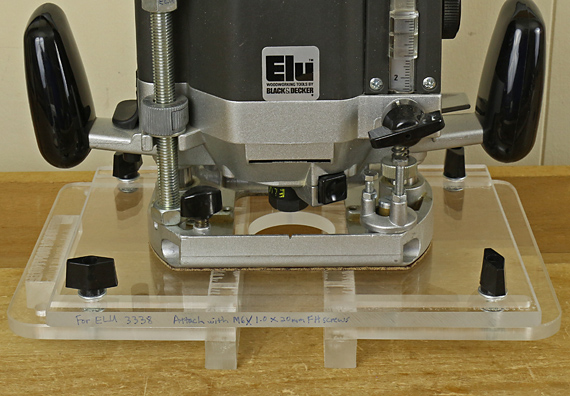

The system starts with an auxiliary router base plate that rests on top of the squared leg blank and has two adjustable fences that hug the sides of the blank to eliminate side play. I have been using the one shown here, made from acrylic, since I bought it from Woodhaven more than 25 years ago.

Though it is no longer available from Woodhaven, it does not seem difficult to make a similar version from plywood, perhaps lining the fences with adhesive UHMW plastic. The base is about 10″ wide and 8″ deep. Each fence is an L-shaped construction. The long arm of the L has two slots, in which slide bolts that pierce the base and are tightened to fix the fence position. The short (1″) arm of the L rides along the side of the leg blank.

It probably would be good enough to substitute the L fence with just a flat piece of plywood, though the height of the fence is added insurance against tipping. Alternatively, you could slot the base and use simple hardwood strips for the fences. I trimmed the fences to ensure that no part of them extends beyond the base plate, so it is only the base plate that will meet the stops that define the mortise length, as you will see later.

The idea is nothing more than a double-sided router fence.

So, that’s simple enough. Now we need two more elements. First, is a way to reliably register the workpiece in place, and then clamp it there. Second, we need stops to define the ends of the mortise (and a haunch, if required). To make the jig adjustable for different layouts, these stops must adjust independently from the workpiece-registration element and clamps.

Below is an overall view. It is really simpler than it might look at first. Trust me, I hate complicated jigs – I’ll break down this one for you in upcoming posts.

By the way, the plunge router is an Elu 3338, vintage about 1990 and still mortising strong. It is very similar to the current DeWalt DW625, though the Elu was made in Switzerland.