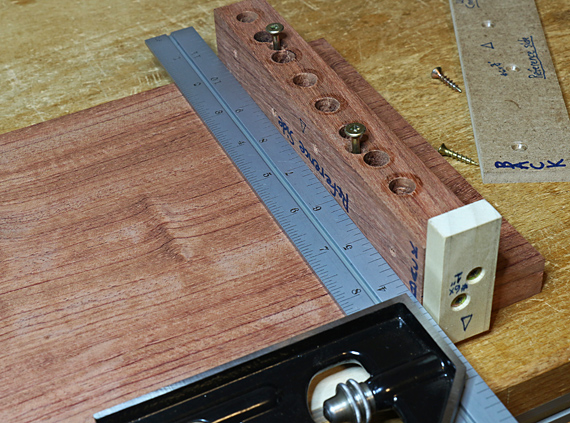

Continuing with the carcase dowel joint, shown above is the reference face of the jig being squared to the inside of the carcase. This is the same reference face of the jig to which the side piece was attached as the jig was screwed into place on the end grain workpiece. (See the photo in the previous post.)

The jig’s end cleat references the placement to correspond with the end grain workpiece. Note that the end cleat should be a bit narrower than the jig itself to avoid interfering with the placement of the square, as seen above. I usually prefer to clamp the jig to the side grain workpiece and recheck it for square before screwing it down.

Keep track of your references. You can see why I label the jig so much. In this build, the reference face of the jig corresponds to the inside faces of both workpieces.

I drill all the holes with a portable power drill. I find no need to use a drill press or, if I had one, a horizontal boring machine. The carefully made jig ensures accuracy.

Below, left, the brad point bit is for the cross grain holes but it is slow and tends to burn when drilling along the grain. For that, the DeWalt Pilot Point (middle) bit is my favorite. The standard twist bit on the right works well enough too. Check the actual diameters of the bits to keep the holes consistent.

I have never seen an oversized good quality bit in these categories; they all seem to be made with a one-sided tolerance toward the small side. I suppose this is because all drilling systems have at least some runout, and you can make small holes bigger but not big holes smaller.

Please don’t use masking tape as a depth stop when drilling these joints. One slip of the tape can ruin a lot of work. And it will happen. So, is there a good drill stop out there? Yes, but you have to make it. But it’s easy. Please see this post.

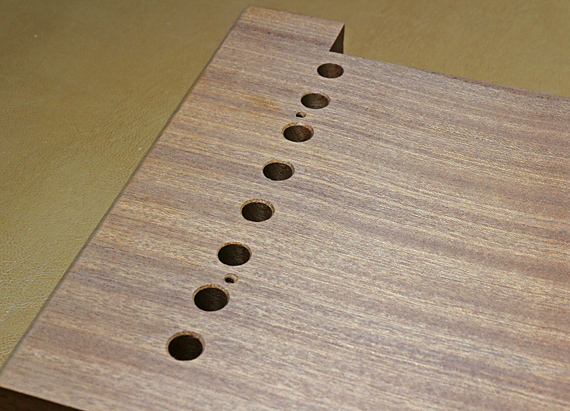

Add chamfers to all the holes – long grain and end grain. This will help with excess glue, and to prevent raised loose chips, which can prevent the joint from closing fully.

Next, we’ll look at dowels, gluing, and some joint design considerations.