Maybe.

Of course, the best drill stop is on a drill press but the topic here is drill stops for hand drilling, which for most of us means with a portable electric drill, corded or cordless. So, let’s look at the candidates.

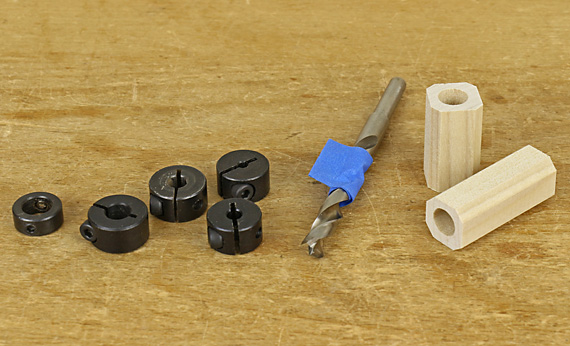

The most common store bought drill stop is a round metal collar with a single setscrew that tightens against the drill bit. These are cheap and not bad, but I’d stop short of calling them good. Most of them tend to tilt as the screw is tightened and all of them can damage the flutes of the bit. If you jiggle or turn the collar to direct the point of the setscrew toward the bottom of a flute and then tighten the screw carefully and firmly, they can stay put and perform decently. Fuller makes a version of these that is longer than the others.

Another type of stop uses a setscrew to close the metal collar’s diameter to bind it by friction against the drill bit. I’ve found that the metal is too stiff to reliably close down snugly against the bit, or on the other hand, that the inside diameter is too close to that of the drill bit so the collar is too hard to get on or off the bit. They’re borderline acceptable; I wouldn’t call them good.

Some of the stops used in conjunction with a countersink are pretty good and some of the Forstner bit stops seem good but those are other matters.

An utter failure is the red plastic stop that twists on and supposedly tightens against the drill bit. I have found them totally unreliable – they easily slip. Sorry, I wouldn’t use them in a hundred years on any project of importance.

Now let’s look at what I think most of us use: masking tape. Wrap some blue tape tightly around the drill bit and squish it in against the flutes. Then fold over the last bit of length so it forms a little flag that sweeps away the drilling dust on the work piece to signal that you are at full depth, and later to make the tape easier to remove.

In any careful work, I put a mark on the drill bit at the bottom of the tape with a Sharpie. Then, as I’m drilling successive holes, I check repeatedly to see if there is a gap between the mark and the tape, which would indicate that the tape has slipped. Alternatively, I keep checking with a ruler.

What about for very careful work, especially drilling many holes, such as in carcase dowelling? For this, remove all doubt and make a dedicated wooden collar drill stop as James Krenov recommended.

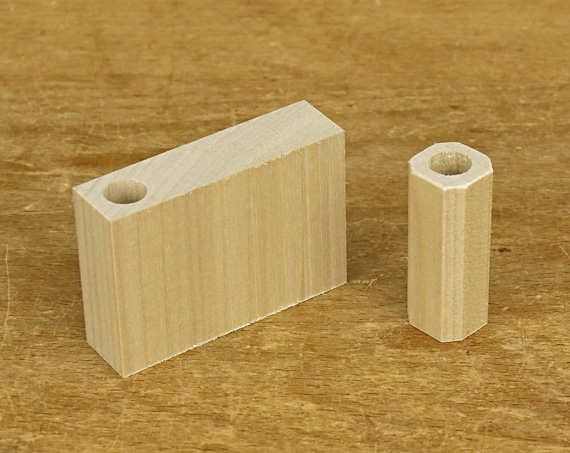

Work out the required length according to the desired depth of the hole and the length of the drill bit. Use a drill press to bore into the end grain of an over-wide squared block then saw off the stop itself. Chamfer the long corners for safety so they won’t hack at your fingers. If you cut the cross section of the stop to size before drilling, it will register less accurately against the drill press table and the drilling is likely to be dangerous.

The cutting depth can be fine tuned by adjusting the amount of the drill shank inside the chuck – assuming it is a good chuck. This type of drill stop has never let me down. It’s worth the extra effort. By the way, dentists understand this.

So, yes, there is a good drill stop, but you have to make it.

Hi Rob,

I use the exact same wooden stop as you’ve pictured. The hole at the base that meets the drill will eventually assume the shape of the taper on the chuck. My work involves drilling thousands of holes and this simple stop does the job. The way I use it is to place the point of the bit into the small hole that’s punched (usually) and then slide the stop so it is square as it meets the wood surface and hold it so it won’t spin, then turn on the drill and push. If you don’t hold it the drill can make the stop spin against the work and bruise it , creating a burnished circle around the screw hole.

Hey Tico,

Great point and technique about avoiding bruising on the wood from the stop. Alternatively, most of the depth could be drilled with the stop against the chuck (where it is from drilling the previous hole) and then bring it down and hold it against the wood for the last 1/8″ or so of drilling.

I’m using these stops mostly for carcase dowelling so its not a factor there.

Rob

Never have seen that method. I’ve been using the painter’s tape, but like you I’ve had it slip, which defeats the purpose. I like the Krenov idea (not the first time I’ve uttered that statement).

Yea, Bailey, me too.

I use a piece of plastic or rubber tubing cut to length. Since most of my freehand “stopped” holes are for dowels or pegs (1/4″ or 3/8″) of some kind, standard tubing sizes will fit the drill bits. Save the used pieces in the same container where you keep your loose drill bits, etc.

Neat idea, Tom. Thanks. I think the tubing material would have to be non-compressible or minimally so.

Rob

Ruland on Amazon has some quick-clamp collars that look very attractive. Climax also makes a large variety of shaft clamps, some of which are a two-piece design that might conform well to drill bits. My best current drill stops are from China and have relatively long collars, two set screws, are well made and zinc plated to prevent the rust that afflicts my Fuller drill stops.