Dry fit the joint with just two dowels. Using all five dowels makes it remarkably difficult to disassemble. However, check every one of the long grain holes to make sure it is full depth so you don’t get a surprise when finally closing the glued-up joint.

I find it less stressful to glue up in two stages. I apply glue in the holes, and then tap in the dowels in one of the tongued components. I limit the depth of the dowels with a registration block. When this subassembly has dried enough to keep the dowels stable, I complete the glue up by applying glue to the other set of holes, plus a little bit on the dadoed piece, and then push the whole thing together.

This joint must be clamped from the ends. I have found it strongly tends to stay accurately square but, of course, I check it anyway, and adjust the clamps as needed.

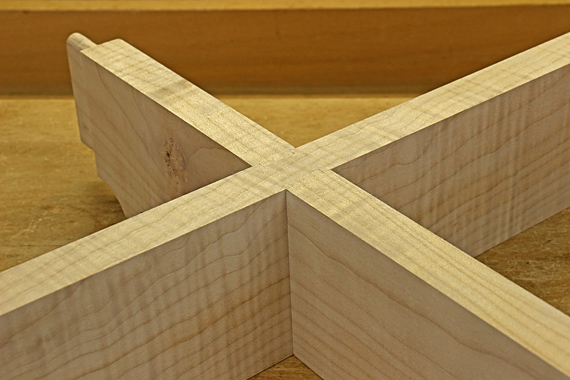

When the glue is dried and conditioned, I plane flush the outer edges. If made accurately, which is very likely if the dowel jig was made accurately, this joint will turn out neat and strong, and it will stay that way.

Much of the work in making this joint is in making the dowel jig, which is reusable for a joint of the same or less width. The joint also works with large width rails because there is no conflict from dimensional change due to moisture cycling.

This has been a good joint to have in my repertoire. You might want to give it a try.

I will soon be building a 10 foot wide by 8 foot tall set of “built-in” book cases and this joinery is one I am considering for joining shelves to uprights. My other considered joinery is tapered sliding dovetails which will put to good use the dovetail plane I purchased for a pittance maybe thirty years ago.

I like the dowel and dado for the minimal reduction it affords with the shallow dados.

What is the minimum depth you would consider for the dados and same for a sliding dovetail?

Dan,

I use 1/8″-deep dadoes for this joint. That fully serves the purpose of the dado. In prototypes, 1/16″ was too little for comfort but I suppose 3/32″ would be OK.

The sliding dovetail is a great joint too. I have found that a non-tapered sliding dovetail longer than even about 2 inches or so is a royal PITA. So, use a tapered sliding dovetail for > 2″. The depth of the dovetail should be about half the thickness of the board but probably never more than that. For 3/4″ stock, I’d say the minimum depth for a decent dovetail lock is about 1/4″.

Keep in mind that the cross-rail joint is a poor choice for joining a shelf to the side of a bookcase because the half of the joint in the side of the case will not have long grain-to-long grain glue surface. The cross-rail joint would be good for joining a shelf to each of the opposite sides of a vertical partition in the case. For joining a shelf to the case side, go with the tapered sliding dovetail, except at the very top and bottom, of course.

Hope this helps. Good luck with the project.

Rob