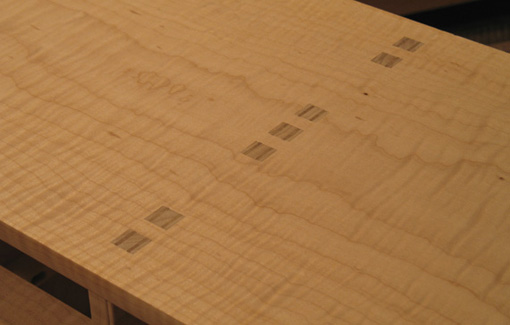

Here’s a seven-tenon version of the MWTM&T joint that is part of a casework project in progress in the shop. The wood hasn’t been varnished yet. I recently wrote an article for Popular Woodworking magazine detailing techniques for producing this joint. The article, using a small sample, explains step by step how to make the joint, with key differences from traditional teaching that make it easier to make, improve the appearance, and add to the long term stability of the construction.

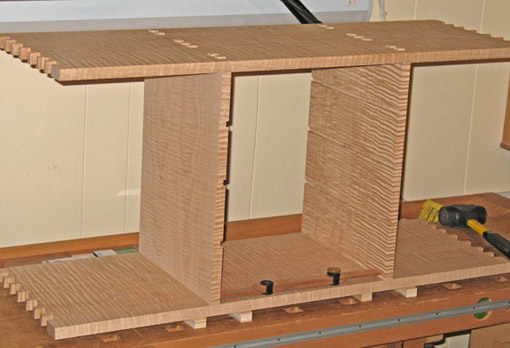

The photo below shows the dry fit with the excess lengths of the tenons still projecting. The pinch rods were used to check the width of the case; going from front to back it widens just a hair to allow proper drawer fitting.

It is a moderately difficult joint to make but the work progresses predictably. Glue up for this piece was tricky but Bowclamp cauls were very helpful in getting a tight joint line along the full width of the boards. Sawing the tenons flush to reveal the finished joint is one of those great moments in woodworking!