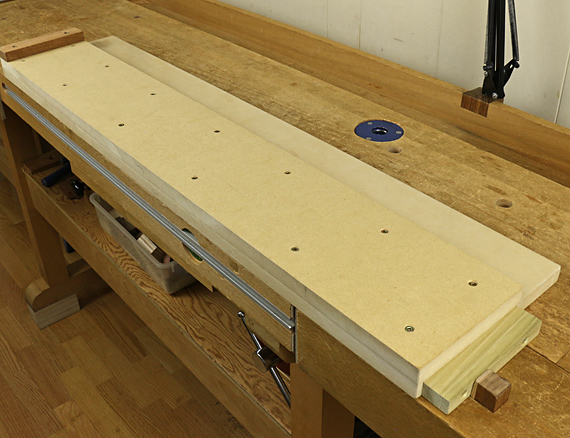

My new jig for long-grain shooting accommodates workpieces up to 36″, a big increase from the old jig’s capacity of 24″. I was motivated by a few occasions when I had to use the somewhat awkward setup of clamping a long workpiece to a support board and running the plane on the benchtop.

I have found that shooting a three-foot long piece is really not a problem with a good setup. And the big jig imposes no disadvantages for shooting much shorter pieces.

My 10/31/19 post is a discussion of long-grain shooting.

Construction is simple from 3/4″ MDF: The workpiece platform is 6″ wide on top of the base, which is 9″ wide, to make a 3″-wide plane runway that is covered with thick PSA UHMW plastic. I like the Lie-Nielsen #9 but any bench plane would work.

The workpiece is controlled from the front by the end stop, and from the side with clamped scraps. I find no need for an elaborate, screw-mounted permanent lateral clamp board because while it would offer some convenience, it would also limit the functional range of the jig. Top (downward) control is supplied by your hand.

When shooting a narrow workpiece, such as a door stile, which might temporarily have a convex or concave non-working edge, there is the danger of the workpiece flexing against the straight edge of the lateral control board. The solution, shown above, is to use two separate lateral control boards, each butted against a section of the (non-straight or suspect) non-working edge of the workpiece.

The cleat at the right end of the jig is an afterthought (you know what I mean: “Doh!”) that allows the jig to be clamped with dogs with a conveniently minimal opening of the tail vise, which is then tightened.

It works beautifully.

I take that unlike end grain shooting you’re doing this to flatten the long edge rather than to square to the end? So presumably when you are preparing a board you shoot the long grain first and then square by shooting the end grain?

I normally joint the edge of a board with the edge clamped upwards on the front of my bench, but admittedly after flattening the edge I always have to do a few passes at the end to square the edge to the face. (Which I should probably do with my rabbet plane but I usually just do it by eye and check with a small square.)

Scott,

Please see above the link to my post that explains long-grain shooting. The full set of nine posts on shooting (end grain, long grain, shooting boards and planes, etc.) is here: http://www.rpwoodwork.com/blog/tag/shooting/

As always, there are lots of good options.

Hope this helps.

Rob

Great addition to your previously written articles on shooting. The shooting attachment for mitres I asked about last time, I’m going to build for a shooting board like you’ve demonstrates in your 9 posts. Thanks for sharing such great knowledge.

In your article on shooting board planes, and where the options ‘rank’ in your experience, I’m wondering what your thoughts are on having a low angle jointer versus a traditional bevel down plane. If you could have only one plane in that length when you were beginning to collect jointer planes ( assuming a jack and smoother were covered already). That way the low angle jointer could be used to joint boards with long grain shooting, shoot wide mitres, and face boards when dimensioning lumber. Thoughts?

Hi Brad,

Great question. Bevel-up vs. bevel-down jointer. I suggest not factoring in long-grain shooting when selecting a jointer plane. Choose based on other considerations just as you would for a jack or smoother. Here’s why.

I do not use a jointer plane for long-grain shooting, even if the workpiece is 36″ long, the maximum capacity of my new long-grain shooting board, or about as long as I’m likely to shoot even if I didn’t have the new jig. The principal advantage of any jointer plane is, of course, its long length. Secondarily, its weight and consequent momentum are also helpful. That long length operates effectively only with a two-handed grip along with appropriate pressure on the front and rear handles at the correct stages of the planing stroke.

But with long-grain shooting, you necessarily are gripping the plane with only one hand, which makes it difficult to truly use the principal advantage of a jointer’s length. The weight and momentum of the jointer may offer some advantages for long-grain shooting but I find those are superceded by the awkwardness of moving such a big plane with one hand.

Therefore, I like the L-N #9 for long grain shooting, and if I were using a bench plane, I’d choose a jack over a jointer. Since I still want to produce a nice straight edge on the workpiece, I overcome the disadvantage of the shorter plane with technique. Specifically, I’ll usually start with two or three shavings, progressively longer, from the middle of the board, working outwards. Then, I go to full length shavings.

That’s my approach. You may find differently but hopefully the reasoning I presented will help you decide.

Rob

Thanks for the response Rob,

I will drop the long grain shooting from consideration. My son and I are hoping to build a mitre plane, similar to the Number 9, as a fun project for us together, which will be helpful as you’ve noted for the different shooting tasks outlined in your discussions.

I am in a sense trying to pick your brain about which plane to choose. We have accumulated a few old Stanley’s (not Bedrocks), and we have had difficulty fettling them to get them to work properly. Could be technique, could be setup, could be a myriad of things. My son has a birthday coming up, and I know he has asked for a jointer plane. The #7 from Woodriver is possible, the LAJointer from Lee Valley would be a consideration as well, and the Lie Nielsen is a little out of reach but I’m sure he would be happy with a giftcard towards it’s purchase.

We work mostly with straight grained wood, not alot of interlocking grain, some reversing grain, and if there is tear out, a cabinet scraper does the job adequately. I appreciate the feedback on long grain shooting, and will drop it out of consideration for the decision of bevel up versus bevel down. Now to figure out which of the 3 to consider for his birthday.

Thanks,

BH

Good luck, Brad.

Rob

Hi Rob,

What is the hand plane shown in the last photo?

Jeff

Jeff, that’s a Lie-Nielsen #9, which they are not currently making as far as I can tell. A jack plane, bevel-up or bevel-down, would work just fine for this job. The sidewall should be square to the sole.

Rob