Here’s more. Looking over my shoulder . . .

Three for the brain:

1. Blue tape reminder not to move a gauge setting. I often like to preserve the setting on a layout gauge until I must change it for another purpose, or at least until I’m positive I won’t need it again. This avoids clearing the setting, only to later find that it is needed for one more piece, such as a remake of a part that I goofed up.

2. Sharpening “recipe” written for each tool. Each tool has its own characteristics and purposes from which evolve the best grinding and honing angles. Experience with a tool may indicate changes in the optimal angles. I keep a recipe sheet of angles for my tools at my sharpening station to save time and confusion.

3. Date glues and finishes when they arrive in the shop. I do this routinely, with a Sharpie marker, to avoid guessing the age of a product when I later go to use it and wonder if its shelf life is over.

Three for the body:

4. Adjustable-height chair/stool. I’m fine being upright if my feet are moving but I don’t like standing for long periods. This compact folding chair gives me relief. I don’t do most woodworking sitting down but there is no need to use my standing endurance for things like chopping dovetails or cleaning pitch from a router bit. The adjustable height comes in handy more often than I would have guessed.

5. Shoes for the shop. Sturdy shoes, such as my low-cut hiking shoes, give me more standing stamina and a better grip on the floor for tasks such as planing, especially as the floor accumulates sawdust and shavings. I run in running shoes but avoid woodworking in them.

6. Wood floor! Many years in my old shop with a concrete floor made me hunger for a wood floor when I set up my current shop seven years ago. The concrete was tiring and not kind to dropped tools. I installed this “floating” wood floor over a concrete slab. After ensuring there was no moisture problem, I leveled the concrete with compound, laid a polyethylene moisture barrier, a thin foam pad, and then the wide-strip, pre-finished red oak flooring. It is not nailed or glued down. There have been no problems rolling a 600 pound table saw and other heavy machinery. A less glossy finish would have been better, so I am considering dulling this floor a bit by sanding it.

Three for the wood:

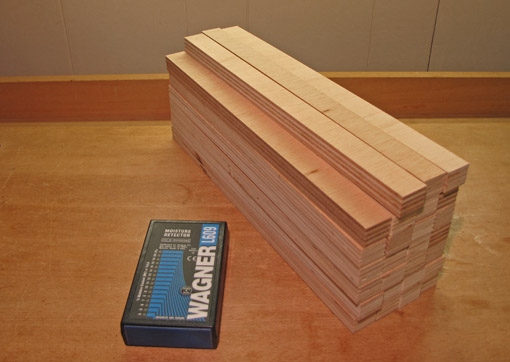

7. Supply of sticks readily available for storing boards. Newly purchased wood is stickered to allow good air flow so its moisture content can equilibrate to the shop environment. It is also important is to similarly store a part that has been dressed for a project rather than sitting it on a pile or bench leaving only one side exposed.

8. Date and note the moisture content of wood as soon as it arrives in the shop. This allows me to monitor changes and avoid guessing when the wood has equilibrated.

9. Consider end coating new wood. If the moisture content of the newly arrived wood is very different from the anticipated equilibrium MC, I coat the end grain with a wax emulsion. This prevents a too-rapid change in MC at the ends of the boards via the end grain pores, and thus possible checking.

Good luck with your current or future projects!

I started a discussion on Facebook about shoes for the shop. I currently use tennis shoes and the group felt as a whole that work boots were much better which I find surprising. Your hiking boots idea sounds much better to me.