For those not familiar with the Tormek grinder, the SE-77 jig, an upgrade over the older SVH-60, holds the blade and slides onto the guide bar, where it rotates to present the blade edge to the grindstone in a very consistent manner. The niftiest features of the SE-77 are its ability to reliably put a controlled amount of camber on a plane blade, and to microadjust the lateral angle of the blade edge to the stone.

The SE-77 has a sturdy build. The left clamp screw slides to adjust the width between the two clamp screws. This more securely holds a wide range of blade widths. There is an end stop on the right side that squarely registers the right side of the blade into the jig, which is useful for blades with parallel sides.

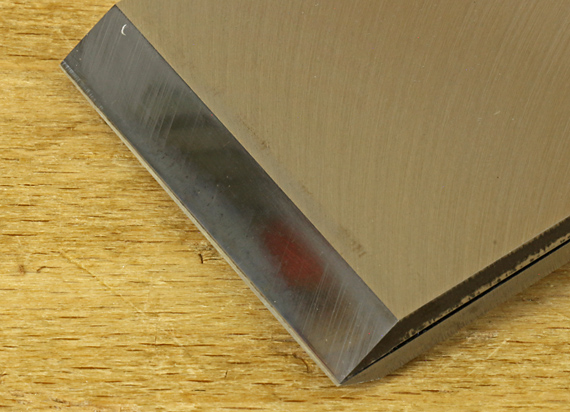

The pair of small thumbscrews, shown in the foreground of the photo below, controls the two special functions of the jig.

To microadjust the lateral angle of the blade edge against the stone, you back off one of the screws and advance the other the same amount. This is much more reliable than shifting and reclamping the blade in the jig.

To camber the blade edge, you loosen both microadjust screws. This creates a pendulum motion about the small stem. (See the photo: the small stem has a brass washer and external snap ring on its end.) With this pendulum motion, you can guide a controlled amount of camber onto the blade edge. The system works very well, though you do have to blend a gradual arc. A too-heavy touch can create a shallow V-point edge instead of a nice smooth camber.

Another welcome feature of the SE-77 is the design of the lower jaw of the blade clamp, which gives a good grip on Japanese chisels (hallelujah!), even onto the shank.

At $66, the SE-77 is not cheap. Having used the Tormek for a many years for grinding – very little on the leather honing wheel – this new jig has been a worthwhile upgrade.

Dear readers, I hope this series on blade camber has been helpful. As always, what I write is born of “the sawdust and shavings of my shop.” These are the techniques and approaches that work for me as I make things. I welcome your ideas and comments.

Rob