Here are three tools worth having.

1.

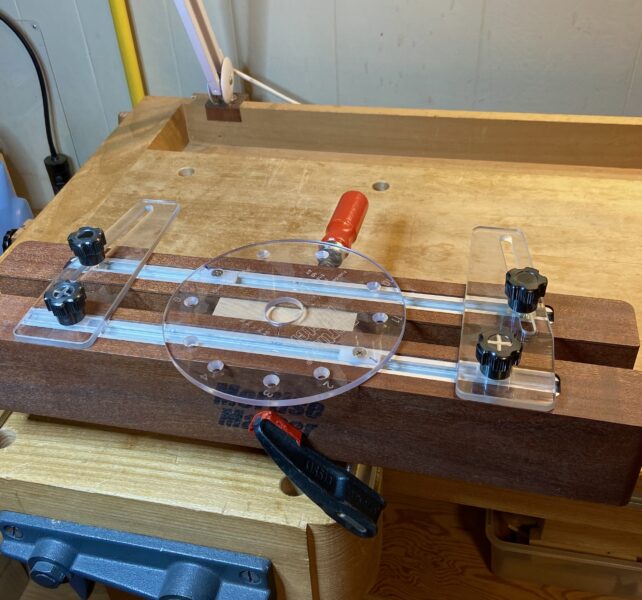

Mortise Master is a cleverly designed way to use your plunge router to make loose tenon mortises. In other words, you simply make a mortise in both wood parts and then add a separate tenon to fit them together.

Does this mean that it will not be a strong joint? No. We well break down this issue in an upcoming post.

Mortise Master has a clever way to keep the mortises laterally centered on both pieces. Just as easy, they both can be set equally off center, or they can be unequally off sided.

The vertical positions are also readily set. The router’s guide bushing sets in the slide plate which is governed by the two metal runners and limited by the screw-held stops on each side.

Work moves quickly and reliably.

It does have a couple of shared limitations. Like most mortising, there is no dust collection. Routers tend to through lots of cutting waste. Also, you cannot, like most basic mortise setups, do angled mortises. That can be done with the Leigh FMT ($) mortice and tenon jig, which takes a lot more learning to use.

I really like this tool! You can get a Mortise Master now for $230 with free shipping. (I have no business/money connection.)

2.

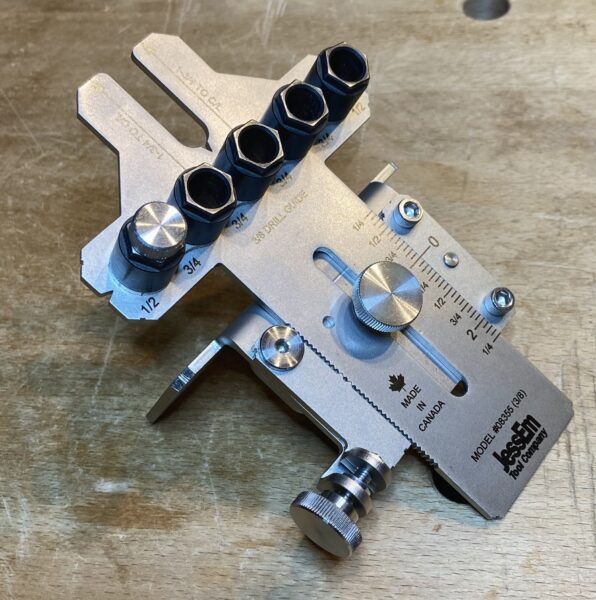

The JessEm dowel joint tool is just great. I have the common 3/8” dowel version. (I will be discussing the grace of dowel joinery in a soon upcoming post.) This very well made tool is accurate, direct and easy to use. You can make small joints or stepwise reposition it to make longer joints.

It has a great precision line up mechanism.

I cannot find a JessEm discussion/demonstration about using the jig to make the dowel holes across the flat face of the board. However, it is straight-forward and I have done it very accurately.

Well, I do not think I am going back to my years of using the wooden hole jigs to set out and drill dowel holes.

3.

Leigh makes bench hold-down clamps that I like better than the longtime traditional curved metal holdfast clamps. I never found that even good quality holdfasts grip well without more than a quick bang to set it up.

The Leigh tool bench connection does not set up quite as fast as the old kind, but once it is set up, it quickly grips on and off the woodwork. You simply move the lever at the top.

A useful help that I think Leigh should supply at the rather expensive cost of this tool: The “speed nut” that fits underneath the bench top can be awkward in some situations. It can also loosen and even drop off occasionally. I made a simple wood piece (about 3 1/2” long, 1″-square thick) with a full-length hole. A framed nut is screwed into the wood. It attaches to the tool’s long screw at the bottom. It holds fast and well.

I have no business/money connection in any of these tools. They are worth your try!