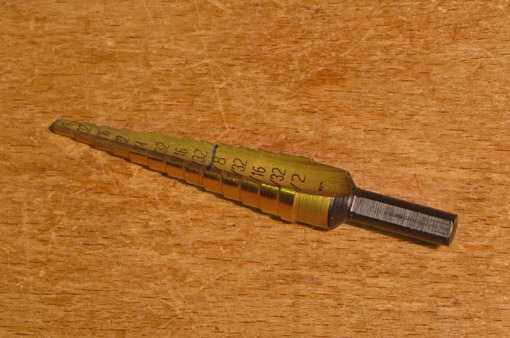

It is usually difficult to accurately concentrically enlarge a hole, especially when working with unpowered or electric hand-held drills instead of a drill press. Furthermore, the sides of the previously drilled hole tend to grab the larger bit and pull it in faster and deeper than desired, sometimes creating a ragged rim at the top of the enlarged hole. A simple tool that has saved the day for me a number of times over the years is the step drill bit.

The one I use, pictured above, has 13 steps, each 1/32″, from 1/8″ to 1/2″. Simply seat the appropriate diameter step in the original hole and drill down to the step of the desired size. It may be helpful to mark the desired step. The resulting shallow hole at the top can now concentrically register a regular bit for the new hole size. Of course, this won’t manage every situation, but it is a helpful option to have in the shop. I have never found a bit with 1/64″ steps.

These bits, sometimes called “drill tree” bits, are designed for drilling in thin metal and plastic, and for that I have found nothing better. They advance smoothly and produce a very clean hole with none of the grabbing or tearing common with regular twist bits.

They are available at home centers and hardware stores. It pays to keep an eye out for tools that are not intended for woodworking but which can nonetheless be useful in the wood shop. “Step drill” can also refer to concentrically ground twist bits, similar to those used for drilling pocket holes. W.L. Fuller in Rhode Island makes an incredible selection of step twist bits, including custom tooling.

Correcting one’s mistakes and finding a way out of jams are like every other skill: with enough practice, you get good at it. I’ve given myself plenty of practice, so I hope passing on these little tips will be helpful to you.

Cool. They are new to me.

These work so well in sheet metal, I never considered them for woodworking. I’ll have to give this a try.

Thanks!

I’ve seen these bits around, but I never really knew what they were for. And now I wish I had one!

There have been far too many occasions where I picked the wrong bit to begin with and then struggled to enlarge it without making a mess of things.

The bonus of not drawing the bit in farther than I want would be wonderful – I don’t have a drill press yet and am constantly battling drilling too deep, too fast.