Here – we – GO!

Let’s look at building a wall cabinet with two frame-and-panel doors. The style can be Krenovian, Arts and Crafts, Shaker, whatever you like. The same principles can be applied to other casework such as boxes and chests. I will make the somewhat artificial distinction between a table saw-centric and a bandsaw-centric craftsman. As discussed in the previous post, this is not a question of using one machine to the exclusion of the other, rather it is about which tool tends to guide your approach. Furthermore, this does not imply that one machine defines a craftsman’s entire methodology; obviously there are other tools in the shop.

Wood is selected, and the project starts with the case top, bottom, and sides. The table saw woodworker is likely to accept one of the sawmill’s edges of each board as starting points. After flattening a face and thicknessing, that edge is jointed and the opposite edge is ripped parallel.

The bandsaw guy is likely to start with more design freedom and not assume that the case will have straight edges, but even for a customary case with rectangular components, he has more opportunity to sensitively make the most of the wood. One of the most common pitfalls early in a project is automatically accepting the board’s edges that were sawn at the mill. The bandsaw guy studies the board and extracts the best parts, unfettered by the original orientation of the figure.

Resawing, the bandsaw’s forte, gives the freedom to seek out and use excellent wood in any thickness. For example, matched sides could be created from a figured billet.

Well fans, it looks like the bandsaw is doing moves the table saw has never seen. Ouch.

Wait, you say, isn’t it more accurate to rip the opposite edge parallel on the table saw? Yes, and if the table saw is available, use it. However, the advantage is small, especially with a well-tuned bandsaw. Furthermore, in both cases, the most accurate and well-surfaced final rendition of fitted edges will come from a handplane.

What about crosscutting? Again, the table saw has an advantage but it is only a little more trouble, and it is more controlled, to shoot the ends by hand which can be done after they come off the bandsaw.

The bandsaw is an MMA fighter and the table saw is a classic boxer.

Let’s consider making the doors. This is where the fight goes to the ground. With the bandsaw you can easily resaw a beautiful boardto make bookmatched panels that will be the best feature of the piece. Yes, you can resaw with the table saw but it is awkward and limited. Resawing is a gateway technique that can change how you think about wood.

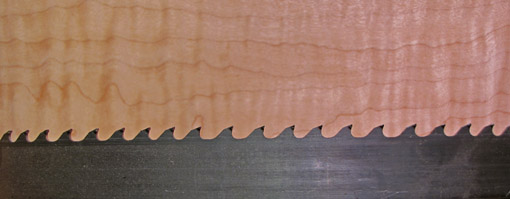

Ha, you say, making the door rails and stiles has got to be where the table saw has the advantage. Yes and no. Once again, the all-important management of the wood is best done on the bandsaw. The figure in the wood used for the frame should be harmonious. Some craftsmen even like to resaw and bookmatch these pieces. The inside edges of the frame members will come off the jointer (hand or machine), and it is handy to then rip them on the table saw. However, for fine work, the width of these pieces will be cut a bit oversize and the final fitting of the doors to the case is best produced with a hand plane. A bandsawn edge is an adequate starting point for that.

Creative, interesting handles for the doors are more likely to come from a shop with a bandsaw.

And so the table saw taps out.

The main points are that the bandsaw facilitates more creativity in design, and far more artful use of wood. Though the table saw does have advantages in ripping and crosscutting accuracy, these are easily circumvented by using the bandsaw in conjunction with hand tools in an incremental, controlled approach to fitting the parts of a project. In short, a bandsaw-centric approach can produce better craftsmanship.

Next: The Rematch. Let’s look at how this applies to making a table. Now this could get ugly.

Great points made here.

I’m leaning towards getting a good bandsaw and keeping my dw744 rather than upgrading it to a bigger one. I really like the idea of being able to resaw.

Yes the tablesaw is more accurate. But only a little. I have amazed some of my power tool shop guys when I show them what my 608 does to their edge joints that they thought were ready foe glue- up. Hard to improve on a well tuned tablesaw with a good blade for crosscutting. But a huge issue for me is the comparisons of the hazards involved with both tools. Not even close. I have heard of more and more pros who use the table saw less and less for this reason.

The resawing capabilities of even my very modest old craftsman 12″ bandsaw made me really happy to use the tool. As you say Rob, it changed the way I thought about the work.

There’s also something inherently more satisfying to me about using the bandsaw. I think it’s related to its automated hand-tool like quality (which is connected to the safety issue too – another thing that makes me more comfortable with it!). With the BS, you’re always there at the cut and you can move the workpiece how you want. With the TS (and router) the circular motion and nature of the tool(s) makes the cut often hidden, so you just end up having this machine where you feed wood in one direction and it spits out – hopefully not back at you! – some finished thing out the back end.

Patrick,

I suggest get a good steel frame bandsaw with at least 12″ of resaw height. Minimax and Agazzani make great saws. Grizzly and Rikon make nice less expensive saws.

Ron,

I agree. I’m more at ease working with the bandsaw.

Aaron,

Yes, I call the bandsaw a “hand tool with a motor.” See:

http://www.rpwoodwork.com/blog/2010/06/15/bandsaw-hand-tool-with-a-motor/

All,

Thanks for reading and for the comments.

Rob

Great approach to this topic Rob.

I had a 10″ Delta contractor saw for about 15 years before I bought my Laguna bandaw (16″ Italian model) two years ago (after years of research). I bought it for the ceramic guides and fit and finish which is superior to the Chinese/Taiwan versions. Since I bought the Laguna I think I’ve turned the TS on once.

I always go to the BS first (and plan cuts based on it) because I think its a much safer machine and I think the finished cut is better. Combining a great machine with a terrific blade (I LOVE Laguna’s 1.25″ Resaw King) gives me much more confidence with any cuts. I plan to make cuts in sheet goods and dados with the Festool tracksaw system with their saw and routers.

In fact, just last week I bought my brother-in-law a 19″ Grizzly BS (my generosity has limits) and I’m going to get him a Resaw King blade. That way he’ll know why I rave about BS work and he won’t be shoving his hands into a TS blade when the sharp-as-heck Resaw King requires so little force even in hardwoods.

My advice to those shopping for a machine: buy the best biggest machine that you can and definitely buy a top-notch blade – it’ll improve the performance of an inexpensive machine. Get larger than a 14″ machine if you can.

Hand tool with a motor is a great description Rob.

Hi Rob

This debate has been around awhile and you make some good points.

I think the main point is that both machines are good at different things. Yes you can make do with only one, but maximum versatility comes from using both.

I’m not so sure, however, with your statement that most tablesaw users would accept a factory straight edge. Wouldn’t most tablesaw users start by jointing a face (which doesn’t require a straight edge) and then joint an adjoining edge, before moving to he tablesaw. At least this how I do it.

But I do agree wholeheartedly that it’s more likely hat someone starting on a bandsaw may look to optimize the grain and figure in a board and not saw parallel to and edge. It’s a mind set thing.

I enjoy your blog. Thanks

Joe,

Sounds like a good deal for your brother-in-law. Be careful though, I hear the Italians also make some great sports cars.

Claire,

Thanks for the comment. Please note that in the third paragraph of the post I am not saying that TS users accept the factory “straight edge.” In fact, I’ve stated a procedure that is essentially the same as you use – flatten a face, then joint an edge, then rip. I am not suggesting anyone place a rough-milled edge against a table saw fence, which is a potentially dangerous procedure.

What I am saying is that the TS user is likely to place the edge from the mill on the jointer bed (after flattening a face, of course) and thus be locked into the original figure orientation of the board, rather than exploiting the full potential of the board, which the bandsaw facilitates.

I think we agree.

Thanks for reading.

Rob

Instrument maker Doug Berch’s recent post illustrates this last point very well (and with typical good humor):

http://dougberch.com/dulcimer-fretboards-future/#utm_source=feed&utm_medium=feed&utm_campaign=feed

Thanks Tico. Doug makes beautiful use of the wood in his dulcimers.

http://dougberch.com/dulcimers/

Rob

This article is interesting. I was right with my decision to go for a band saw, after all. Now that I changed from my local supplier to http://www.sawblade.com , I feel that better craftsmanship is close at hand.

I use my bandsaw a lot. Especially for rips. On thick stock I rip a little oversize and plane to width. On thinner stock I finish with a less than blade width rip which I feel is a lot safer since there is little or no off cut to bind the blade.