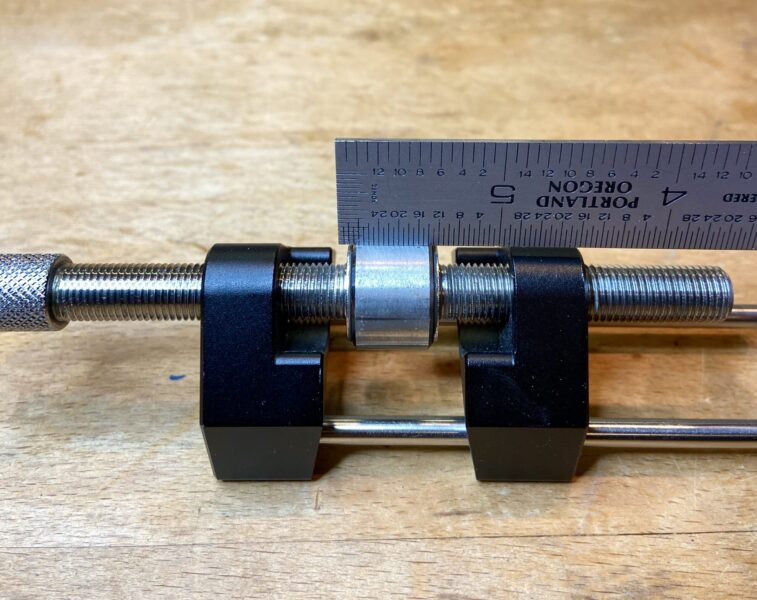

When we hand sharpen a tool, such as a chisel or plane blade, it must be accurately and consistently held at the desired angle to the stone. Most woodworkers and most teachings use an angle holder.

With some exceptions such as tiny or odd blades, I generally do not. I do have a metal gauge that I use sometimes, and that will be covered in a future post here. I have also tried others in the past, and wrote about some, but I do not use those anymore.

Let me explain what I do. Perhaps you want to give it a try if you do not do it already.

The steps:

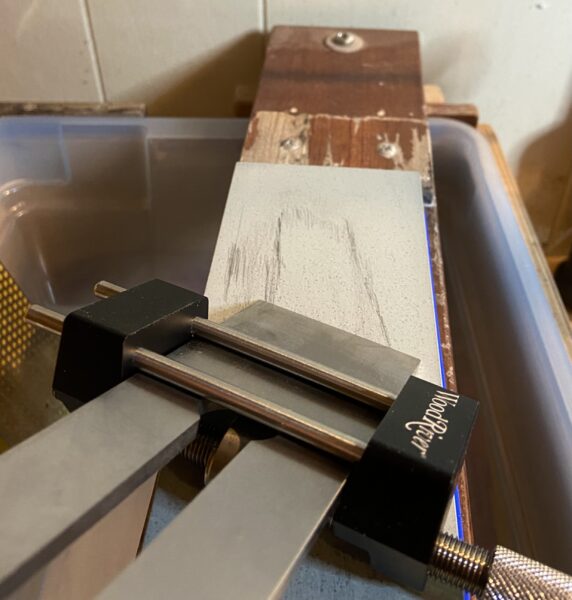

1. Use a very flat stone with just a little water – not a big puddle.

2. The wooden angle gauge is placed on the stone with the left hand. With the right hand, the tool edge is angled firmly into the slot. (See below.)

3. The left hand puts aside the gauge and then works with the right hand to hold the tool angle to the stone. Lock the angle in your hands! (See the picture at the top of this post.) You will be surprised how accurate and consistent you can be after just a little practice. Test yourself.

4. Now cut back and forth for small distances. I usually go only about a couple inches, even less, on the fine stones, while more on the medium and course stones. You must hold the angle steadily over the distance. With some tools, longer feels better.

Most of the cutting occurs on the push rather than the pull.

Some folks like going in a circular back and forth motion. That works too.

Here is what you can sense:

Feel the angle with your hands with balanced, steady legs and body.

Hear the sound of cutting, especially forward.

Sense the edge on the blade on the cutting stone.

With all of these, you can sense slight differences with the correct angle compared with a decrease or increase. I do find all of these a bit easier with the finest stones compared with the coarser stones. If you think you may have changed the angle, recheck it with the wooden gauge.

For practice, try intentionally increasing and decreasing the angle incorrectly. You can quite readily detect the differences in all those senses. Check yourself with the wooden angle gauge.

All of these skills also apply to sharpening curved edges – done for almost all hand planes. Get used to working across through the curve. This is easier and steadier than using a griped-on, wheeled angle tool.

The most common angle I use is 32.5°. Why .5? For no good reason! I made the wooden gauges long ago and never changed them. It does not matter. Consistency does! 32 would be just fine.

I suggest giving this a try. It is faster than working with metal screw-on gauges. You might like it!

In the next post, I will show the wooden gauges. They are easy to make.