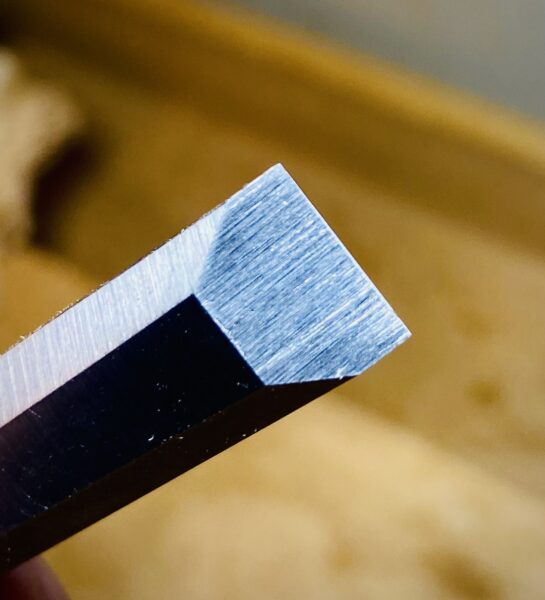

Here is one more thing to add to a manufactured device for sharpening. The previous post explains the issue: for sharpening plane irons that have a slightly curved edge, which is most of them, a subtle curve needs to be added to the roller. (This does not apply to nearly all chisels.)

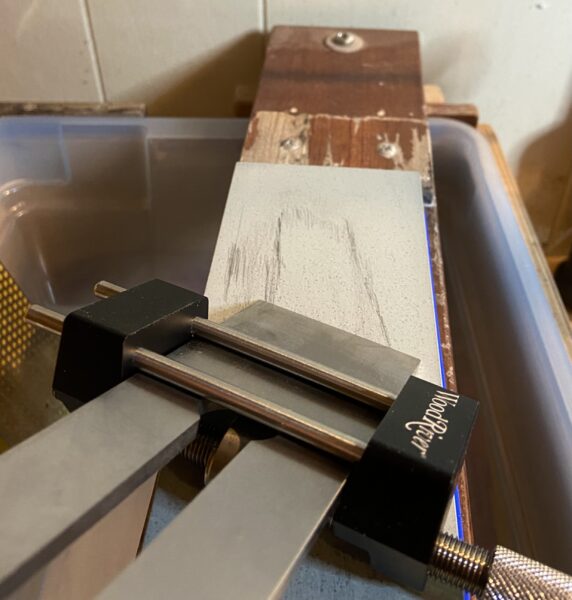

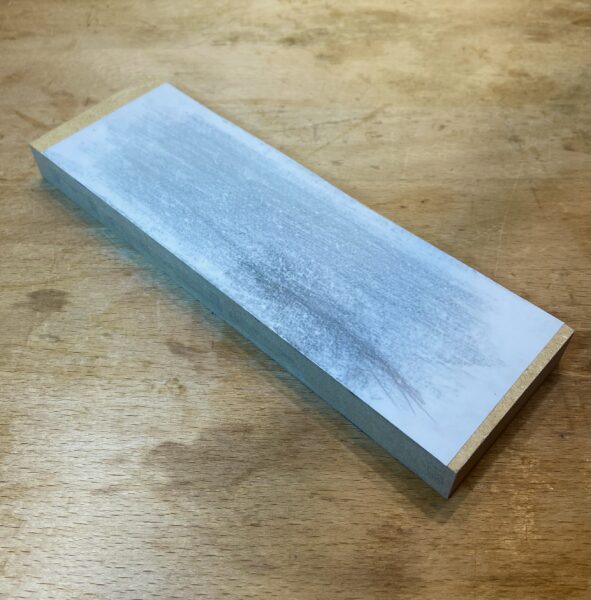

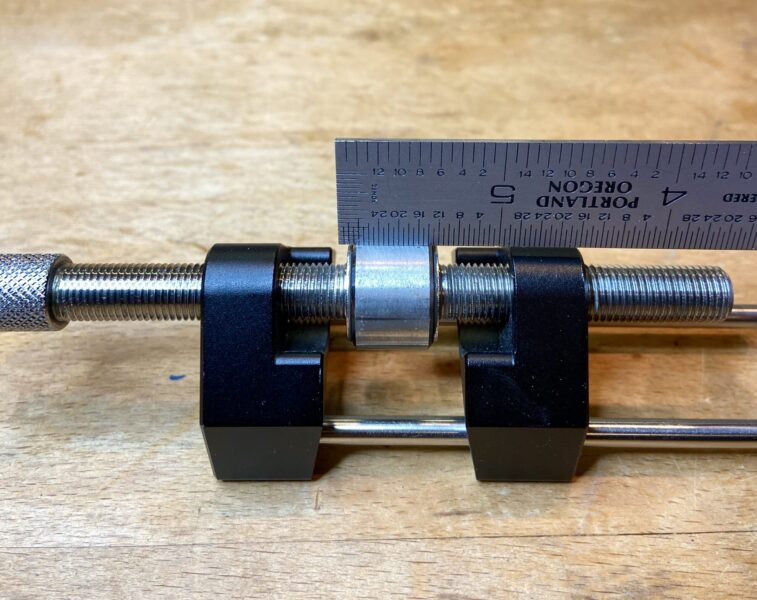

I have two Woodcraft rollers. One is used as is – for sharpening straight edges. (Photo is below.) The other roller is very slightly curved across its width. (Carefully note the photo above.) It was not manufactured that way but was easily done in the shop.

The roller itself is 1/2” wide. Working out the math and using it in practice, reveals that the roller needs to be ground just about .003” on each 1/4” half of the wheel. In other words, from zero at the center point to a maximum curve of .003” shorter at each far side edge.

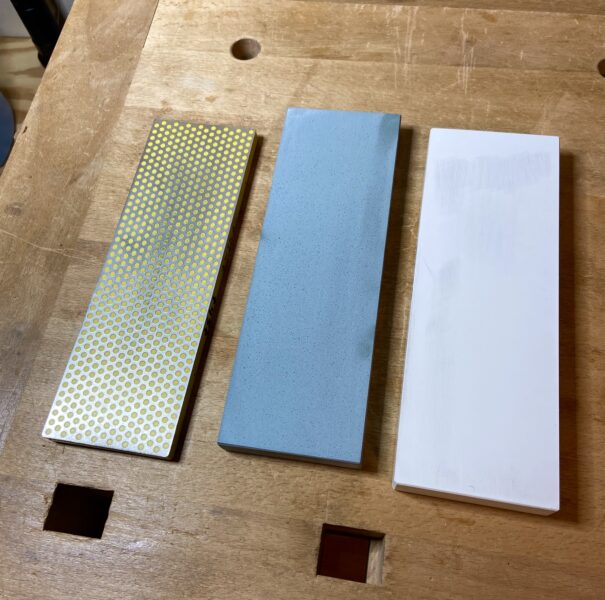

An electric motor-rotating wheel can do this. Be careful and keep fingers away from the wheel! (The safety decision is solely up to you.)

Note that you are making a curved angle on each side, not a straight-edge angle. It is easy to do.

This adds a comfortably controllable ability for angling the plane edge on the flat stone. This is far better than trying to alternately angle onto just the outside corners of a regular flat wheel guide.

This subtly angled wheel will work for almost all of the plane blades. As I have mentioned in the previous post: nearly all manufacturers neglect this important factor. They could simply supply two replaceable wheels or two frame-wheel combinations. (Again, Lee Valley/Veritas is the only manufacturer that I know of that builds in the curvature in one of their wheels. I do not care for their expensive system but I do suggest taking a look online for your choice.)

With all of this said now, I will still say that I do the vast majority of sharpening by the total hand-holding method discussed three posts ago. But now you have options!

Sharpening is a must for good woodworking but not hard to do with the right equipment and skills!