These wooden dogs grip a work piece using the rectangular openings in your bench top. They are easy to make and better than anything you can buy. I only use the steel ones that came with my bench over 40 years ago for very tall pieces of wood.

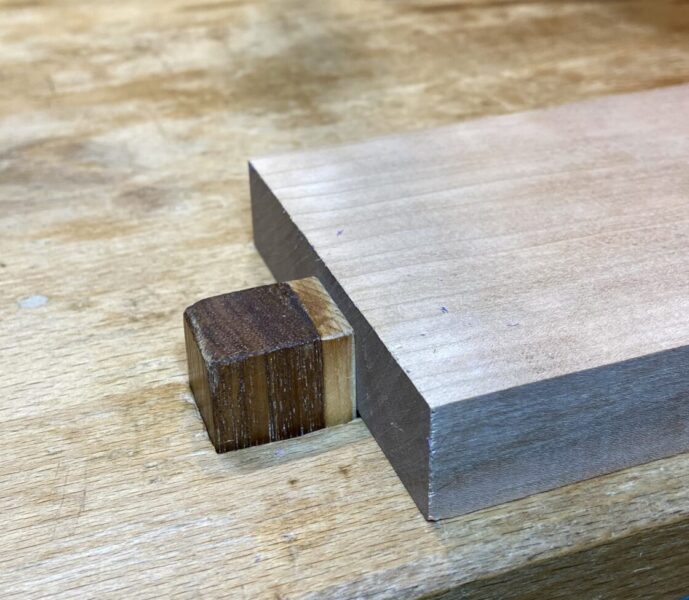

For the frame, use moderately dense wood, 6″ long. The side width is just under 7/8″ to fit in the width of the 7/8″ hole in the bench top. The front-to-back width is 13/16″ which works well in my bench. The corresponding hole dimension in my bench is 15/16″ in its full linear width, and 7/32″ greater in the upper 1 1/4″ of hight.

Alter the dimensional figures for the dog construction to similarly conform to the criteria of your bench.

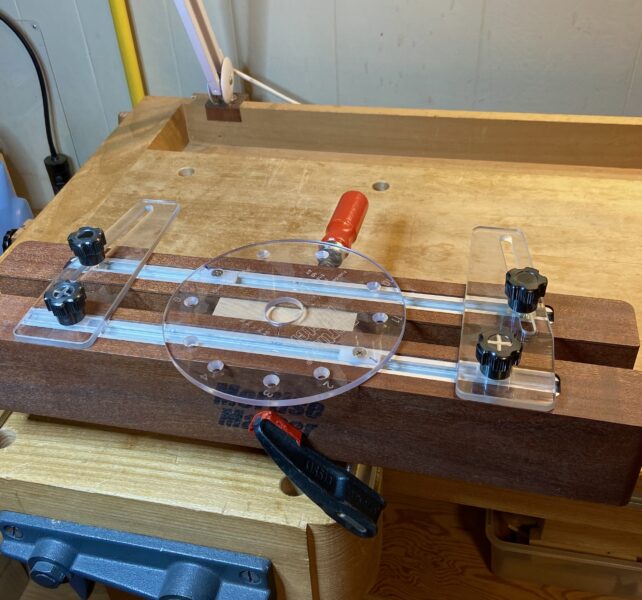

Now plane the bottom 2 1/2″ to taper to about 5/8″ at the bottom edge. To that now-angled surface, screw in a 1/8″ strip (see the photos just above and below) of fairly flexible wood that is 1/8″ thick and 5″ long.

Now glue a piece of fairly soft wood, such as pine, 1/4″ thick and 15/16″ long, to the top portion of the frame, as you see in the photos. This serves as the contact to the work piece. Also, the sideways hole in the dog frame allows you to hang it up near your workbench, if you want.

These dogs will stand securely up to about 1 3/4″ above the bench surface. This covers 95%+ of the needs.

Make a pair, finish them if you want, and you’re done! Eventually, you probably will need to replace the 1/4″ heads. Cut the original off, chisel the service clear, and glue on a new one.

The dimensions quoted herein are based on the dimensions of my workbench as described. If necessary, adjust your building dimensions using the same principles to make the dogs fit your bench.

Wood will not get dented by these dogs, and they grip securely. You can easily adjust the hight of the dogs to avoid bumping them with the plane of other tools.

These dogs work.